Our ability to plan methodologies and design, develop & implement solutions for time critical projects is second to none. Our dedication and passion for welding HDPE goes further than just the welding process, we like to be involved early on in the development stage so we can assist and advise one what will achieve the best outcome for the client with an asset they can have confidence in and will stand the test of time.

Services We Offer

Butt fusion welding is the hot plate welding of thermoplastic pipes. Pipe ends are brought together in a chassis of a machine where two separate pipes ends are clamped, faced square & joined together.

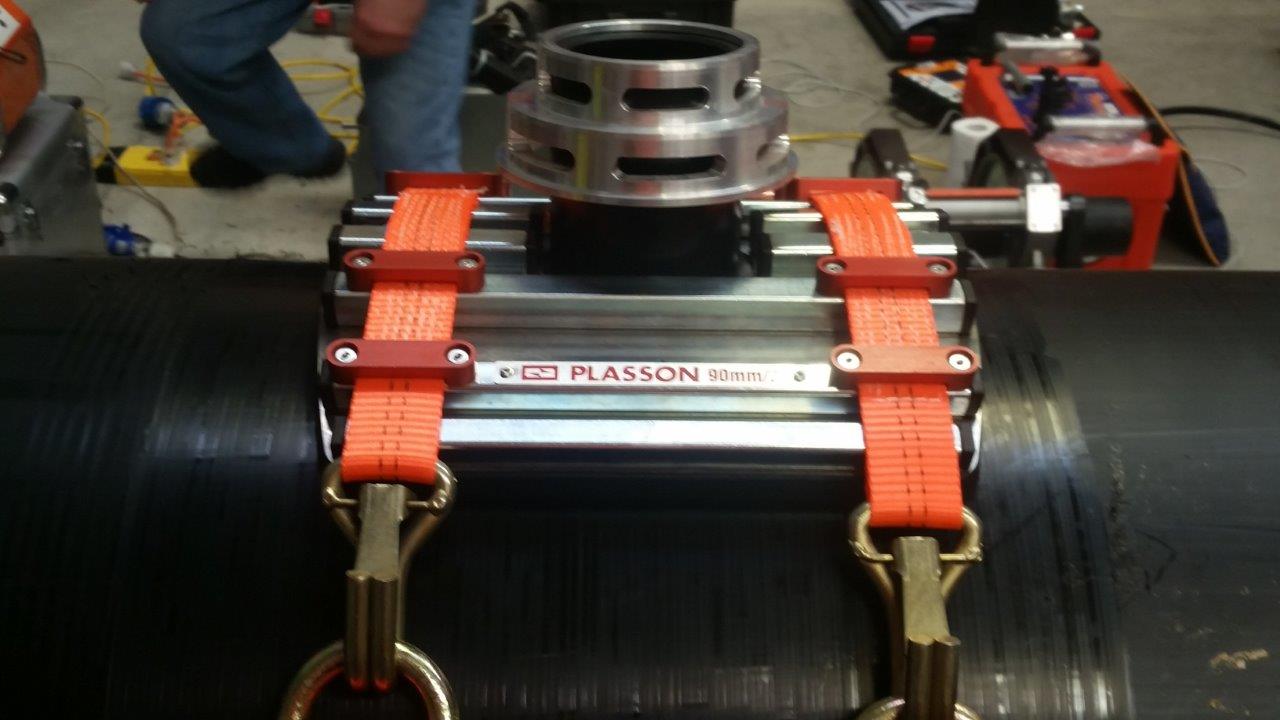

The electrofusion welding process involves the use of a moulded socket fitting containing an electrical resistive heating coil. The prepared pipe ends are inserted into the sockets where it is clamped & joined.

Extrusion welding is used in the manufacture of thick-section fabrications, such as tanks and pipes, where it is necessary to produce large volume, homogeneous seams in a single pass.

Need to turn a corner or offset a pipe to avoid a clash with an existing service? Fusion Solutions site specific fabricated pipe bends allow for such challenges to be overcome quickly and with minimal delay.